Plastic injection

Plastic injection

Plásticos Llorens is a plastic injection company that manufactures all kinds of parts through a process of plastic injection. The company works with all types of thermoplastic materials, whether technical or conventional, as well as PP, ABS, PPA and PBT. The company also works with multiple-load materials like fibreglass, mineral fillers, additives for UV protection and V-O flame retardants. In addition, it uses engineering materials, such as long-fibre materials, carbon materials, materials with densities 2-11 g/cm3, and electric and thermal conductive formulations, all with UV resistance, V0 flame retardants and antistatic. We respond to challenges that clients need to overcome, delivering a 100% optimum performance.

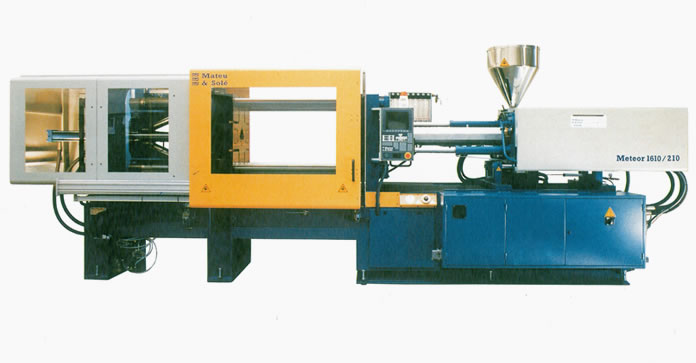

We develop a diverse range of products of different types, shapes and sizes. Products include small precision components to larger dimension products, in a range of weights starting from 1 gr to 1’5 kg. All this is possible due to the company’s high injection technology with a machinery pool of 30 TN to 320 TN. In this sense, we are versatile and can perform a complete range of plastic injection projects.

Plastics Llorens manufactures parts from client moulds, as well as from moulds designed by its in-house technical team. The company conducts testing processes to ensure optimum production of parts.

Plásticos Llorens also offers complementary postproduction services, such as assembly of parts or end finishes, which include printing, pad printing, plating and chrome, as well as packaging according to client indications (includes: bagging, packaging).